Plastics and the Oceans

Target description:

- Support initiative and scientific research on microfibres, work with core suppliers to reduce microfibre release

- Research biodegradable polyester for use in PUMA products

- Eliminate plastic bags from PUMA stores and review the impact of hangers and fixtures

Relates to United Nations Sustainable Development Goals 3, 14 and 15

KPIs:

- Tons of plastic bags used in PUMA stores

- Percentage of PUMA offices that have eliminated single-use plastic

- Percentage of plastic packaging recycled

Plastic pollution in our oceans is one of the most urgent challenges to sustainability of our time. As a company that uses polymers for most of its products, we have a special responsibility to work on this issue. Avoiding plastic pollution is one of the three pillars of the Fashion Pact, of which PUMA is a founding member. Also, several countries and regions have formed initiatives to ban certain types of single-use plastics or plastic bags.

Therefore, we have added Plastics and the Oceans to our 10FOR25 Sustainability Strategy as well as our sustainability bonus targets.

2021 | 2022 | 2023 | Target 2025 | |

Plastic consumer shopping bags (stores, tons) | 189 | 99 | 0 | 0 |

Plastic consumer shopping bags recycled content (%) | 80% | 80% | NA | Zero plastic bags |

Plastic hangers used in stores (stores, tons) | 134 | 160 | 176 | Switch to recycled content or wood |

Plastic hangers with 100% recycled content (%) | 97% | 99.9% | 99.9% | 100% |

Primary and transit* plastic packaging (tons)** | 558 | 2,297 | 3,057 | Switch to recycled content or paper |

Primary and transit* plastic packaging with recycled content (%) ** | 100% | 99.6% | 99.5% | 100% |

Offices that have eliminated single-use plastic cups and cutlery (%) | 88% | 91% | 92% | 100% |

|

|

|

|

|

* Transit packaging from factory to warehouse

** 2023 full year data is proliferated based on actual Q1-Q3 data and 2022 record.

Plastic shopping bags and single-use plastics aggravate the problem of plastic pollution significantly. By eliminating them from our stores and office environment, we have set a positive example for our consumers and colleagues and at the same time reduced our use of plastics by several hundred tons per year.

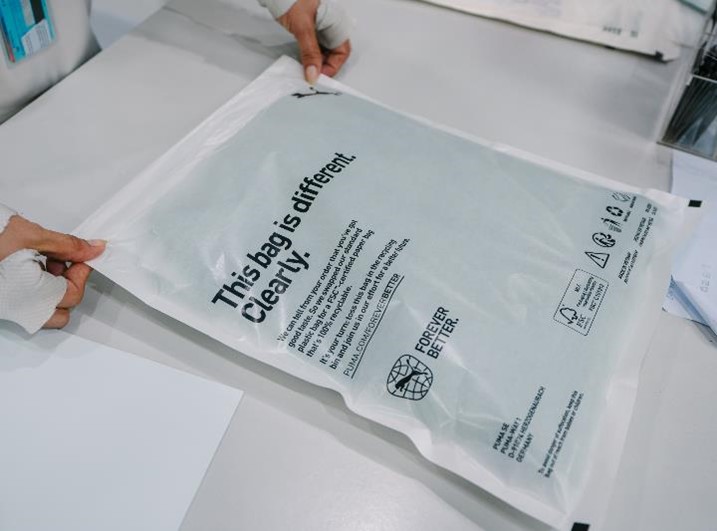

In recent years we switched our shopping bags to FSC-certified paper bags.

Our stores ordered 430 tons of consumer-facing polyethylene bags in 2019 and 400 tons in 2020. In 2021 our stores ordered 189 tons. Finally, in 2022 our stores ordered 99 tons of consumer-facing plastic bags. As of January 1st, 2023, we have replaced all polyethylene bags for consumer use with paper bags or durable multi-use bags for sale in our owned and operated PUMA stores.

At the same time, we switched other plastic items in our retail stores, such as hangers and shoe fixtures, to recycled polymers or FSC-certified wood. We also started working on more environmentally friendly solutions for our B2B product packaging for apparel and accessories, which is also based on polyethylene bags. As a result of these efforts, we switched our transit packaging B2B plastic bags to 100% recycled content and also optimised the thickness to save on weight. Our labeling and packaging team is investing time and resources in exploring environmentally optimised packaging solutions. For example, we piloted transit bags made from paper in the USA. In 2023 we rolled out transit bags made from FSC-certified paper for selected products.

According to our zero plastic target for primary product packaging, we also switched most B2C plastic primary packaging to paper. For the few remaining plastic items like hangtag strings, we worked on non-plastic or recycled plastic alternatives. At our offices, we have challenged our catering partners and employees to avoid single-use plastics such as coffee cups, lids, stirring sticks, cutlery or straws. In 2021 88% of our offices globally had already eliminated single-use plastic cups and cutlery. This figure increased slightly to 91% in 2022 and 92% in 2023.

FSC certified packaging for apparel products

On a product level we finished the pilot experiment of a compostable version of our most iconic sneaker, the PUMA SUEDE. The pilot included the use of a fully biodegradable outsole made from thermoplastic polyurethane (TPU). For more information on RE:SUEDE, please refer to the Circularity section of this report.

MICROFIBRES

All types of fibres have a propensity to shed to some extent, and understanding the full impacts of their physical and toxicological presence is a growing area of research therefore we must not limit our focus to synthetic materials.

Led by science, The Microfibre Consortium (TMC) seeks to understand both the drivers of fibre fragmentation and, through external sources of research, the impacts on human health and ecosystems, such that we can collectively take the right actions to mitigate negative impacts. PUMA joined The Microfibre Consortium (TMC) as one of the signatory members to understand and address the environmental concerns surrounding fibre fragments (microfibre) as generated from natural and synthetic clothing during manufacture and the consumer use phase in the industry.

In 2023, we continued with microfibre shedding tests to measure microfibre release from our polyester products during washing. We conducted 12 tests on selected 100% polyester fabrics following the TMC test method to quantify fibre loss from fabrics that reflect that found in domestic laundering, during the initial washing cycle. Fibre release results are expressed as a percentage of mass. The tests results indicate that microfibre loss from PUMA's fabrics is lower than the average microfibre loss available on the Microfibre Data Portal. Specifically, PUMA's average 0.0579%, compared to the TMC database average of 0.0587%. For related definitions, please visit Static.

We have received feedback from TMC regarding the shedding data, and we understand that analysing it is complex and ongoing. So far, there is not a clear trend showing which yarn or structure type sheds more among the signatories. TMC has requested more data entries, and we will continue to participate in and support this study as an industry.

In October 2023, PUMA joined a field trip to King's College London with 40 other delegates. TMC teamed up with specialist test instrument manufacturer James Heal to hold the first public demonstration of the TMC Test Method for fibre fragmentation from fabric.

PUMA remains committed to the TMC 2030 roadmap released in September 2021. PUMA has pledged to support this roadmap and its objectives, including increasing the understanding of fibre fragmentation through research, implementing mitigation strategies once they become available in the industry, and contributing to progress through active participation in task teams with a goal of global implementation.