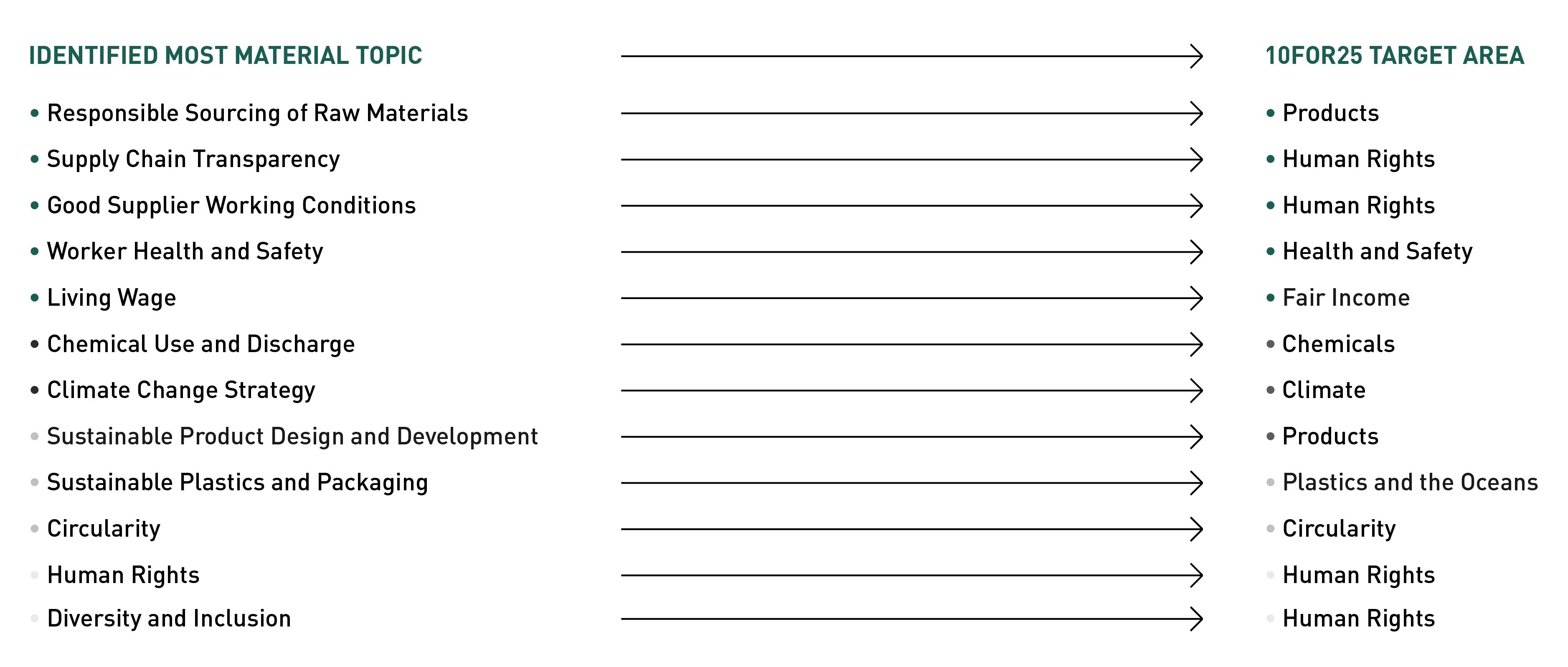

Most Material Aspects

PUMA performed a formal materiality analysis in 2018 – 2019 with the help of expert consultancy BSR. The methodology, list of consulted stakeholders, and results were reviewed and approved by PUMA’s Managing Directors. Materiality assessment results are also considered in the risk management process. Our risk management function assesses our most material topics and the risks related to those topics in collaboration with the risk owners. The 2019 materiality assessment formed the basis for our existing PUMA FOREVER. BETTER. Sustainability Strategy and 10FOR25 targets, as well as the structure of this 2023 report, and is outlined in the graph below. Further details on the methodology can be found in PUMA’s 2022 Annual Report.

↗ G.04 PUMA’s Most Material Aspects (2018 – 2023)

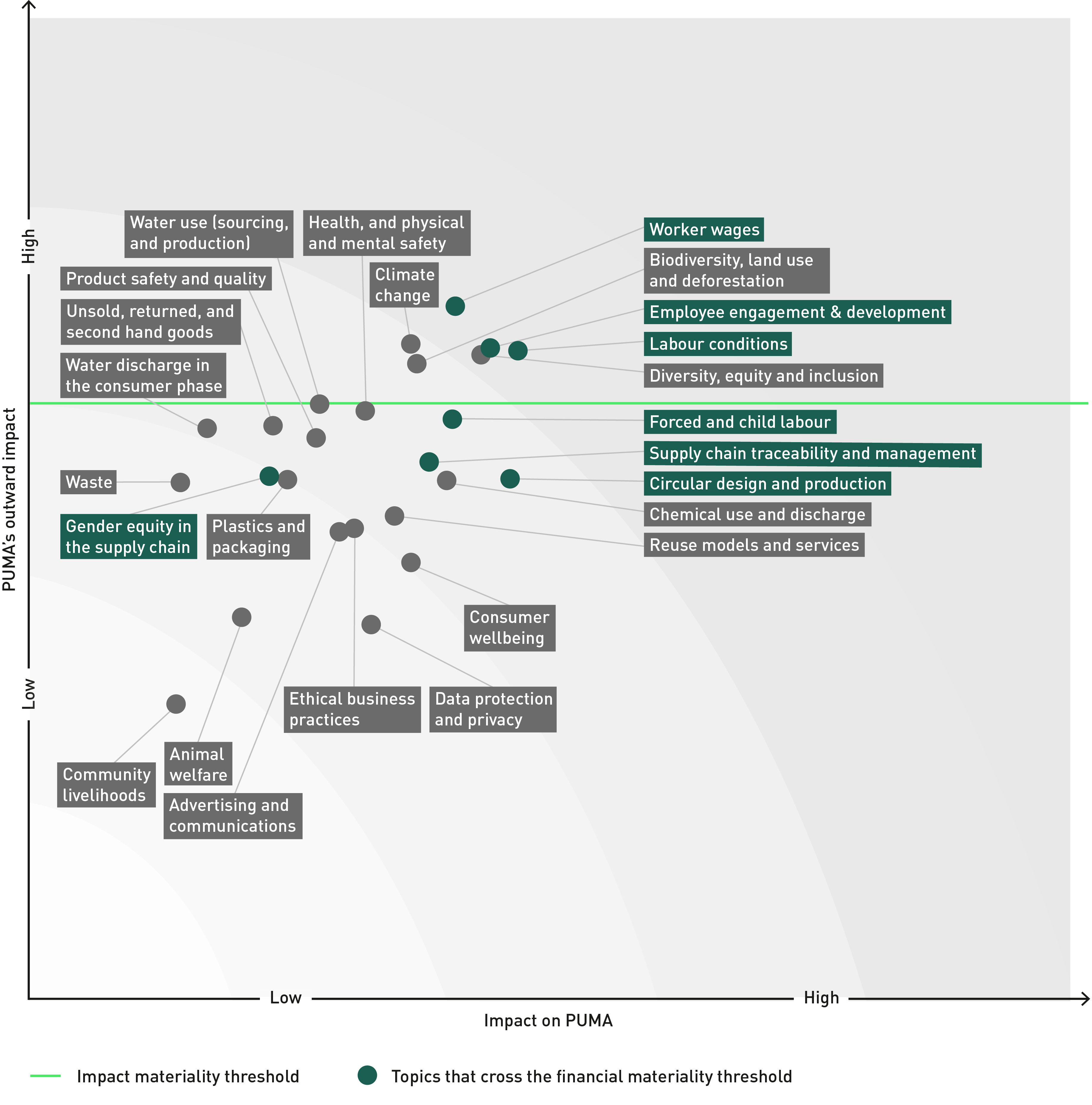

DOUBLE MATERIALITY ANALYSIS – 2024 AND BEYOND

In 2023, PUMA conducted an updated materiality analysis based on the principle of double materiality as requested by the Corporate Sustainability Reporting Directive (CSRD). The methodology, list of consulted stakeholders, and results were reviewed and approved by PUMA’s Managing Directors (CEO, Chief Financial Officer, Chief Product Officer and Chief Sourcing Officer). PUMA’s CEO, the Chair of the Supervisory Board, and a Workers Council representative participated in the materiality assessment.

The 2023 materiality assessment was conducted by the expert consultancy Radley Yeldar and included:

- A horizon scanning stage, including peer benchmark assessment, legislation, sustainability frameworks and ratings, and media screening

- Development of CSRD-compliant impact assessment criteria

- Stakeholders interviews with 32 participants, including 16 PUMA and 16 external stakeholders as well as an online survey (37 responses)

- Out of the interviews, eight in-depth interviews for financial impact were conducted, including investor and lender views

- Results validation meetings between PUMA’s Sustainability Team and Radley Yeldar

- Managing Directors‘ approval

A total of 25 sustainability topics were selected after the horizon scanning stage to be evaluated by stakeholders. Seven topics were identified by our stakeholders as being financially material to PUMA.

Social topics:

- Forced and Child Labor in the supply chain

- Gender Equity in the supply chain

- Worker Wages in the supply chain

- Labor Conditions in the supply chain

- Employee engagement and development of own workforce

Other topics:

- Circular Design and Production

- Supply Chain Traceability and Management

Seven topics were assessed to have a significant outward impact.

Social topics:

- Worker Wages in the supply chain

- Labor Conditions in the supply chain

- Diversity, Equity, and Inclusion of own workforce

- Employee Engagement and Development of own workforce

Environmental topics:

- Water Use in the supply chain

- Biodiversity, Land Use and Deforestation in the supply chain

- Climate Actions in the value chain

Notably, Labor Conditions, Worker Wages, and Employee Engagement and Development passed both the financial and outward impact threshold for materiality. All eleven topics, targets and achievements, identified as material (from a financial and outward impact perspective) are already included in this report. Going forward, we will transition from our 10FOR25 targets toward our 2030 strategy, which will be based on the new materiality assessment and the outcome of our stakeholder dialogue in 2024.

↗ G.05 PUMA’s DOUBLE MATERIALITY MATRIX

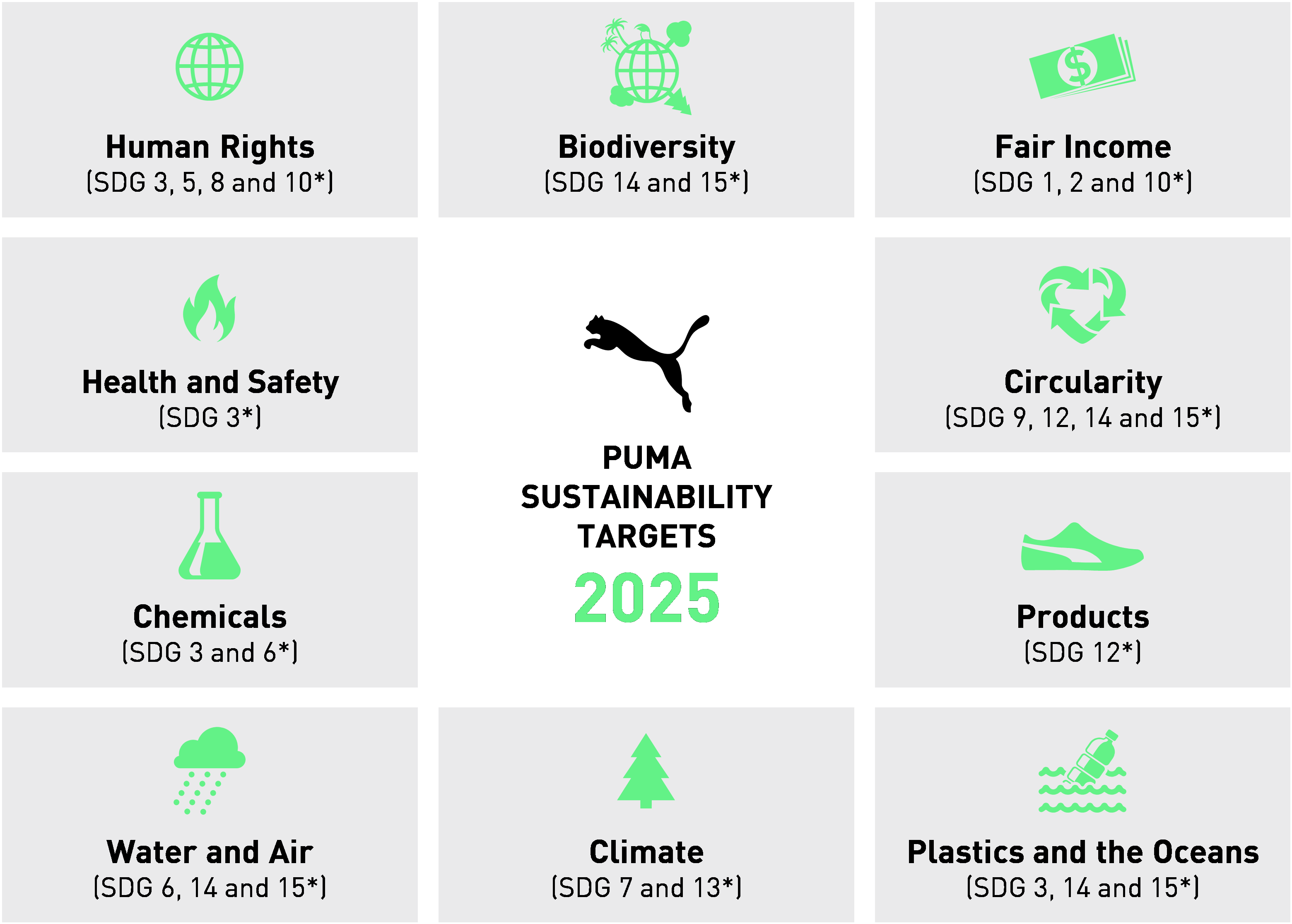

↗ G.06 PUMA’s 2025 SUSTAINABILITY TARGETS

*SDG: United Nations Sustainable Development Goals

Not started In progress On track Achieved

Targets for 2025 |

Performance 2023 |

Status |

|

|

Target 1: Train 100,000 direct and indirect staff members on women’s empowerment |

222,933 factory workers and 3,727 PUMA employees trained |

|

01 |

Target 2: Map subcontractors and Tier 2 suppliers for Human Rights risks |

Tier 1 subcontractors mapped |

|

Human Rights |

Target 3: 25,000 hours of global community engagement per year |

57,000 hours |

|

|

Target 1: Zero fatal accidents (PUMA and suppliers) |

Zero fatal accidents at PUMA |

|

02 |

Target 2: Reduce accident rate to 0.5 (PUMA and suppliers) |

0.46 at PUMA |

|

Health and Safety |

Target 3: Building safety policy operational in all high-risk countries |

ACCORD Bangladesh: Progress rate 94% |

|

|

Target 1: Ensure 100% of PUMA products are safe to use |

No product recall from the market |

|

03 |

Target 2: Maintain RSL compliance rate above 90%* |

6,130 tests with RSL compliance rate at 98.7% |

|

Chemicals |

Target 3: Reduce organic solvent usage to under 10 gr/pair |

VOC index at 12.5 g/pair |

|

|

Target 1: 90% compliance with ZDHC Wastewater Guidelines |

Conventional parameters: 99% |

|

04 |

Target 2: 90% compliance with ZDHC Air Emissions Guidelines |

Our core Tier 1 and Tier 2 follow local regulation |

* |

Water and Air |

Target 3: 15% water reduction per pair or piece based on 2020 baseline |

Textile: -4.9% per ton |

|

|

Target 1: Align PUMA’s climate target with 1.5 degrees global warming scenario |

SBTi approved our new 1.5 degree aligned target for absolute GHG emission reduction: Scope 1 and 2 by 90%, Scope 3 by 33% in 2030. Our first 2019 SBT achieved in 2023. |

|

05 |

Target 2: 100% renewable electricity for PUMA entities |

100% renewable electricity used for PUMA entities (including RECs purchase) |

|

Climate |

Target 3: 25% renewable energy for core suppliers |

23.1% for Tier 1 (finished goods) |

|

|

Target 1: Eliminate plastic bags from owned and operated PUMA stores |

As of 1 January 2023, plastic bags are no longer used in PUMA’s owned and operated stores |

|

06 |

Target 2: Support scientific research on microfibres |

Signed 2030 commitment of microfiber consortium, 12 shedding tests conducted |

|

Plastics and the Oceans |

Target 3: Research biodegradable plastics options for products |

RE:SUEDE experiment as a test for biodegradability completed and results publicly shared |

|

|

Target 1: Establish take-back schemes in all major markets |

Take-back schemes established in at least one country in each of Americas (the USA), Europe (Switzerland) and Asia (Australia) |

|

07 |

Target 2: Reduce production waste to landfills by at least 50% compared to 2020 |

64.7% reduction of waste to landfill per footwear pair |

|

Circularity |

Target 3: Develop recycled material options for cotton, leather and rubber |

Recycled cotton used at scale |

|

|

Target 1: Procure 100% cotton, polyester, leather and down from certified sources |

99.2% cotton |

|

08 |

Target 2: Increase recycled polyester use to 75% (apparel & accessories) |

64.9% recycled polyester used for apparel and accessories |

|

Products |

Target 3: 90% of apparel and accessories classified as more sustainable |

87% apparel volume |

|

|

Target 1: Fair wage assessments for the top five sourcing countries |

Five out of five assessments completed (Bangladesh, Cambodia, Indonesia, Vietnam, China) |

|

09 |

Target 2: Effective and democratically elected worker representatives at all core suppliers |

66% core Tier 1 factories have elected worker representatives |

|

Fair Income |

Target 3: Ensure bank transfer payments for all core suppliers |

100% core Tier 1 and Tier 2 suppliers use digital payment |

|

|

Target 1: Support setting up a biodiversity SBT |

Sponsored a biodiversity landscape analysis report with Textile Exchange and Fashion Pact |

|

10 |

Target 2: Procure 100% cotton, leather, and viscose from certified sources |

99.2% cotton |

|

Biodiversity |

Target 3: Zero use of exotic skins or hides |

Phased out the usage of kangaroo leather during 2023 |

|

|

|

|

|

*ZDHC air emission guidelines have not been yet released at the end of 2023. We have participated in a pilot in collaboration with ZDHC to test the draft standards.

1REC: Renewable Energy Attribute Certificates, RSL: Restricted Substances List, SBT: Science-Based Target, SLCP: Social and Labor Convergence Programme, Tier 1 (T1) suppliers: Supplier of finished goods, Tier 2 (T2) supplier: Supplier of materials or components, Tier 3 (T3) supplier: Supplier of yarn, hides, etc., VOC: Volatile Organic Compound, ZDHC: Zero Discharge of Hazardous Chemicals